FAQ

NYEEM NTXIV

Faults ntawm peb-theem asynchronous motors feem ntau yuav muab faib ua ob ntu: hluav taws xob faults thiab mechanical faults.

Mechanical faults muaj xws li: qhov loj me los yog puas lawm bearings, bearings tes tsho, roj caps, kawg lub kaus mom, kiv cua, rooj zaum thiab lwm yam, thiab hnav thiab rhuav tshem ntawm cov ncej.Hluav taws xob faults feem ntau muaj xws li: stator thiab rotor winding breakage, nruab nrab ntawm lem (theem), mus rau hauv av, thiab lwm yam.

Lub stator thiab rotor yog ua los ntawm kev sib nrig sib insulated silicon steel nplooj ntawv thiab yog ib feem ntawm lub magnetic Circuit Court ntawm lub cev muaj zog.Kev puas tsuaj thiab deformation ntawm stator thiab rotor cores feem ntau tshwm sim los ntawm cov hauv qab no.

(1) Kev coj tus kheej ntau dhau los yog kev sib dhos tsis zoo, ua rau stator thiab rotor rubbing, ua rau cov tub ntxhais nto kev puas tsuaj, uas ua rau lub voj voog luv luv ntawm cov silicon steel daim, ua rau cov hlau poob ntawm lub cev muaj zog, ua rau lub cev kub siab dhau. siab, thaum daim ntawv thov cov ntaub ntawv zoo thiab lwm yam cuab yeej tshem tawm cov burr, tshem tawm cov silicon steel daim luv txuas, ntxuav thiab ces coated nrog insulating xim, thiab cua sov thiab ziab.

(2) Qhov saum npoo ntawm cov tub ntxhais hlau yog xeb vim dej noo thiab lwm yam laj thawj, nws yuav tsum tau polished nrog ntawv xuab zeb, ntxuav thiab coated nrog insulating xim.

(3) Cov tub ntxhais los yog cov hniav raug hlawv vim muaj cua sov uas tsim los ntawm kev sib tsoo lub winding.Ib lub cuab yeej xws li chisel lossis scraper tuaj yeem siv los tshem tawm cov khoom molten thiab qhuav nrog cov xim insulating.

(4) Kev sib xyaw ua ke ntawm cov tub ntxhais thiab lub hauv paus tshuab yog xoob, thiab cov thawj qhov chaw ntsia hlau tuaj yeem nruj.Yog hais tias qhov chaw screws tsis ua hauj lwm, rov tho qhov chaw qhov chaw thiab tapping ntawm lub tshuab hauv paus, zawm qhov chaw screws.

Thaum lub rolling bearing tsis muaj roj, lub pob txha yuav hnov.Yog hais tias lub suab tsis txuas ntxiv tau hnov, nws yuav yog qhov tawg ntawm cov kabmob steel nplhaib.Yog tias cov kabmob sib xyaw nrog cov xuab zeb thiab lwm cov khib nyiab lossis cov kabmob muaj lub teeb hnav, nws yuav ua suab nrov me ntsis.Kuaj tom qab disassembly: thawj zaug tshuaj xyuas lub dov lub cev ntawm cov kabmob, sab hauv thiab sab nraud lub nplhaib steel rau kev puas tsuaj, xeb, nti, thiab lwm yam. Tom qab ntawd rub lub nplhaib puab ntawm cov kabmob nrog koj txhais tes thiab ua rau cov kabmob, thawb lub nplhaib sab nraud. nrog koj txhais tes, yog tias cov kabmob zoo, lub nplhaib hlau sab nraud yuav tsum tig tau zoo, tsis muaj kev vibration thiab pom tseeb jamming nyob rau hauv kev sib hloov, tsis muaj regression ntawm lub nplhaib hlau sab nraud tom qab nres, txwv tsis pub cov kabmob yuav siv tsis tau lawm.Sab laug tes daig rau hauv lub nplhaib sab nraud, sab tes xis tuav lub nplhaib sab hauv steel, quab yuam kom thawb rau txhua qhov kev taw qhia, yog tias koj xav tias xoob heev thaum thawb, yog qhov hnyav hnyav.

Kev kho qhov tsis haum ntawm qhov chaw xeb muaj 00 daim ntawv xuab zeb so tawm, thiab tom qab ntawd mus rau hauv cov roj av tu;bearing tawg, sab hauv thiab sab nraud lub nplhaib tawg los yog coj tus cwj pwm hnyav, yuav tsum tau hloov nrog cov kabmob tshiab.Thaum hloov cov kabmob tshiab, siv tib hom kabmob raws li qhov qub.Bearing tu thiab refuelling.

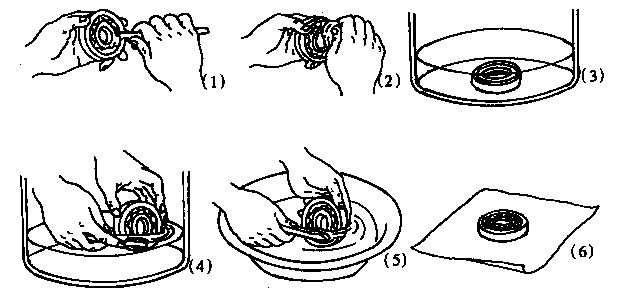

Cov txheej txheem tu cov kabmob: thawj zaug khawb cov roj pov tseg los ntawm qhov chaw ntawm lub pob steel;so cov roj pov tseg uas seem nrog ib daim ntaub paj rwb;tom qab ntawd muab cov kabmob hauv cov roj av thiab txhuam lub pob steel nrog txhuam;tom qab ntawd yaug cov kabmob hauv cov roj av huv;Thaum kawg muab cov kabmob rau ntawm daim ntawv kom cov roj evaporate thiab qhuav.

Bearing greasing txheej txheem: Rau kev xaiv ntawm dov bearing grease, lub ntsiab lus tseem ceeb yog kev ua haujlwm ntawm cov kabmob, xws li kev siv ib puag ncig (ntub lossis qhuav), kev ua haujlwm kub thiab lub cev muaj zog.Lub peev xwm ntawm cov roj yuav tsum tsis pub tshaj 2/3 ntawm qhov ntim ntawm cov kabmob chamber.

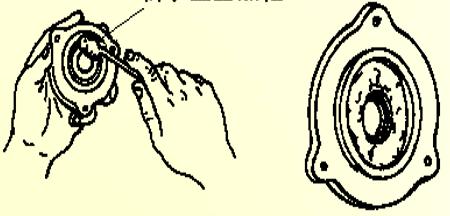

Thaum ntxiv cov roj lubricating rau cov kabmob, cov roj yuav tsum tau nyem los ntawm ib sab ntawm cov kabmob thiab tom qab ntawd cov roj ntau dhau yuav tsum maj mam muab txhuam nrog tus ntiv tes, tsuav yog cov roj tuaj yeem ntxiv kom txog thaum nws tuaj yeem kaw lub pob steel kom tiaj tus. .Thaum ntxiv cov roj lubricating rau lub hau npog, tsis txhob ntxiv ntau dhau, txog 60-70% yog txaus.

(1) shaft dabtsi yog khoov yog qhov khoov tsis loj, tuaj yeem kho los ntawm kev sib tsoo ncej txoj kab uas hla, txoj hlua khi hlua khi;Yog tias qhov khoov yog ntau tshaj 0.2 hli, cov ncej tuaj yeem muab tso rau hauv cov xovxwm, hauv kev txhaj tshuaj khoov siab kho, kho ncej nto nrog tshuab dhos txiav kev sib tsoo;xws li khoov yog loj heev yuav tsum tau hloov los ntawm ib tug tshiab ncej.

(2) Lub caj dab hnav ncej caj dab hnav tsis ntau, tuaj yeem ua rau hauv caj dab ntawm ib txheej ntawm chromium plating, thiab tom qab ntawd sib tsoo rau qhov loj me;hnav ntau dua, tuaj yeem nyob rau hauv lub caj dab ntawm overlay vuam, thiab tom qab ntawd mus rau lub tshuab dhos txiav thiab sib tsoo;yog tias cov ntawv xov xwm hnav loj dhau, kuj tseem nyob hauv phau ntawv xov xwm ntawm 2-3 hli, thiab tom qab ntawd tig lub tes tsho thaum kub teem rau hauv phau ntawv xov xwm, thiab tom qab ntawd tig mus rau qhov loj me.

Ncej tawg los yog tawg ncej transverse tawg qhov tob tsis tshaj 10% -15% ntawm txoj kab uas hla ntawm ncej, kab nrib pleb ntev tsis tshaj 10% ntawm qhov ntev ntawm ncej, tuaj yeem kho los ntawm kev sib tshooj vuam, thiab tom qab ntawd zoo tig mus rau qhov loj me.Yog hais tias qhov tawg ntawm lub ncej yog qhov hnyav dua, yuav tsum muaj lub ncej tshiab.

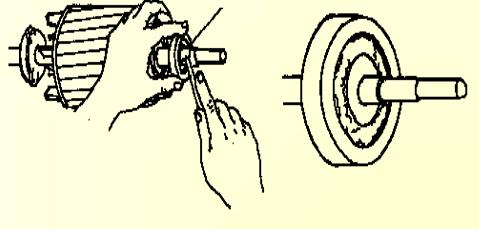

Yog tias muaj cov kab nrib pleb hauv vaj tse thiab qhov kawg npog, lawv yuav tsum tau kho los ntawm kev sib tshooj welding.Yog hais tias qhov clearance ntawm cov kabmob bore loj dhau, uas ua rau cov kabmob kawg npog kom xoob dhau, cov kabmob bore phab ntsa tuaj yeem sib npaug los ntawm kev siv lub punch, thiab tom qab ntawd cov kabmob tuaj yeem muab tso rau hauv qhov kawg npog, thiab rau cov motors. nrog lub zog loj dua, qhov yuav tsum tau muaj qhov loj ntawm cov kabmob kuj tuaj yeem ua tau los ntawm kev sib txuas lossis plating.

Lub cev muaj zog installation puag tsis yog theem.Theem lub hauv paus lub cev muaj zog thiab kho kom ruaj khov tom qab leveling lub hauv paus.

Cov khoom siv tsis yog concentric nrog lub cev muaj zog txuas.Rov kho qhov concentricity.

Lub rotor ntawm lub cev muaj zog tsis sib npaug.Static lossis dynamic ntsuas ntawm rotor.

Txoj siv pulley los yog coupling yog unbalanced.Pulley los yog coupling calibration ntsuas.

Rotor ncej taub hau khoov los yog pulley eccentric.Ncaj lub rotor ncej, teem lub pulley ncaj thiab ces teem lub teeb rau rov tig.

Kev sib txuas tsis raug ntawm stator winding, hauv zos luv luv Circuit Court lossis grounding, ua rau tsis sib npaug ntawm peb theem tam sim no thiab ua rau lub suab nrov.

Txawv txawv teb chaws los yog tsis muaj roj lubricating hauv cov kabmob.Ntxuav cov bearings thiab hloov nrog cov roj nplua nyeem tshiab rau 1/2-1/3 ntawm cov kabmob chamber.

Loose tsiv ntawm stator thiab vaj tse los yog rotor core thiab rotor ncej.Txheeb xyuas qhov hnav ntawm qhov haum, rov vuam, ua haujlwm.

Stator thiab rotor cuav rubbing.Nrhiav qhov siab ntawm cov tub ntxhais hlau, kev sib tsoo ua haujlwm.

Electromagnetic suab nrov thaum lub cev muaj zog ua haujlwm.Yooj yim tshem tawm los ntawm kev kho.

| Rwb thaiv tsev chav kawm | Qhov kub thiab txias (℃) |

| Rwb thaiv tsev chav kawm | Qhov kub thiab txias (℃) |

| Y A E B | 90 105 120 130 | F H C | 155 180 > 180 |

① tsawg viscosity, siab cov ntsiab lus thiab yooj yim ntawm immersion.

② ceev curing, ruaj khov thiab elasticity.

③ Cov khoom siv hluav taws xob siab, tiv thaiv tshav kub, ya raws thiab tshuaj lom neeg ruaj khov.

a) Cov ncej thiab pobzeb qhov sib txawv me dhau.

b) Cov roj zais zis me me qhib thiab cov roj tsis txaus.

c) kub ntawm lubricating roj.

d) Shaft pobzeb tshawb fawb raug mob.

e) cov roj rov qab tsis zoo thiab cov roj tsis txaus.